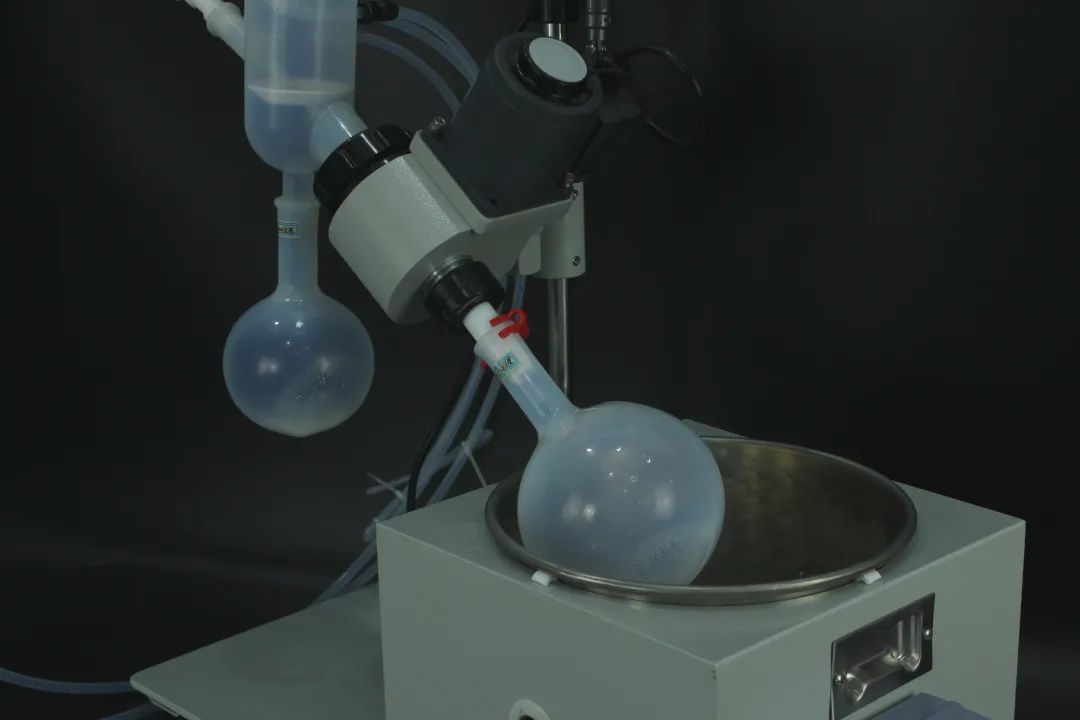

Rotary evaporator, also known as rotary evaporator assembly, is a commonly used equipment in laboratories, consisting of motors, distillation flasks, heating pots, condenser tubes and other parts.

Application:

Rotary evaporators are mainly used for concentration, crystallization, drying, separation and solvent recovery in pharmaceutical, chemical and biopharmaceutical industries. The principle is to heat at a constant temperature under vacuum conditions to make the rotary bottle rotate at a constant speed, and the material forms a large-area film on the wall of the bottle to evaporate efficiently. The solvent vapor is cooled by the condenser and recovered in the collection bottle, which greatly improves the evaporation efficiency.

Product structure:

The distillation flask can be a pear-shaped or round-bottomed flask with a standard ground connection, which is connected to the decompression pump through a high-reflux serpentine condenser, and the other opening of the reflux condenser is connected to a receiving flask through a ground connection to receive evaporated organic solvent. There is a three-way piston between the condensate pipe and the pressure reducing pump. When the system is connected to atmosphere, the distillation flask and liquid receiver flask can be removed to transfer solvent. When the system is connected to the pressure reducing pump, the system should be under reduced pressure. When in use, decompress the flask first, and then start the motor to rotate the flask. At the end of the operation, stop the machine first, and then open the atmosphere to prevent the flask from falling off during the rotation. As a heat source for distillation, it is often equipped with a corresponding constant temperature water tank.

Feature:

1. The distillation flask, the receiving flask, and the condenser tube are made of Teflon and transparent PFA;

2. High and low temperature resistance: operating temperature -200℃~+260℃;

3. Corrosion resistance: resistant to strong acid, strong alkali, aqua regia, hydrofluoric acid and various organic solvents;

4. Anti-pollution: no dissolution and precipitation, low blank value of metal elements.

Parameter:

| RE-201 | |

| Rotating flask capacity | 250ml/500ml/1000ml |

| Receiving flask capacity | 250ml/500ml/1000ml |

| PFA material characteristics | No adhesion to samples, no dissolution or precipitation, low blank value of metal elements |

| Vacuum seal | PTFE plus fluorine rubber double seal |

| Anti-corrosion properties | Resistant to strong acid, strong alkali, aqua regia, hydrofluoric acid and various organic solvents |

| Motor control method | Frequency |

| Range of rotation | 0-120rpm |

| Rotating motor power | 40W |

| Temperature setting display | PID Digital display |

| Temperature control range | Room temperature~200℃ |

| Temperature control accuracy | ±1℃ |

| Heating power | 1500W |

| Evaporation capacity(ml/min) | Water≈20 |

| Heating method | Water bath oil bath dual use |

| Security function | Overload Overvoltage Overcurrent Protection |

| Voltage | 220V/50Hz |

| Condenser | Serpentine condenser |