Product description:

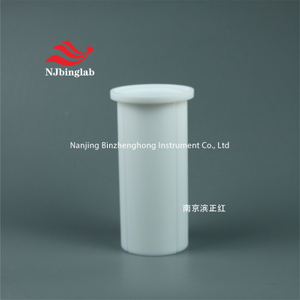

Microwave digestion vessels are internal consumables of microwave digestion instruments. Generally, microwave digestion instruments include inner liners and vessel sleeves. The inner liners are divided into inner plugs, lids, and vessel bodies. Some microwave inner liners are directly lids and vessels without inner plugs. This depends on Microwave Digester Brand and Model.

Features:

Material: TFM polytetrafluoroethylene material, resistant to strong acid and alkali

Dimensions: matching microwave digestion instrument (for example: CEM55ml diameter: 26mm height: 191mm)

Temperature: 260°C, up to 300°C

Pressure: ≥1500psig

Quite low background value (blank value)

Installation steps:

1) Make sure that each liner has been installed with the vessel sleeve. At the same time, ensure that the vessel sleeve is dry;

2) Check the explosion-proof membrane and ensure that only one explosion-proof membrane matching the pressure tank is installed in each pressure relief hole;

3) After strictly confirming that the pressure shrapnel is installed correctly (groove upward), use auxiliary tools to lock the container to prevent leakage;

4) Ensure that medium-pressure and high-pressure reaction vessels are not mixed at the same time in the same batch of reactions;

5) Install the temperature sensor to ensure that the temperature probe is fully installed in the container. Incorrect installation may have serious consequences;

6) In order to standardize the operation of the instrument, the pressure vessel on the turntable should be as uniform and symmetrical as possible, and the pressure vessel should be placed vertically;

7) The pressure sensing line should be placed on the hook on the top plate, and the turntable should be turned for trial to ensure that the temperature and pressure sensing line is not entangled.

Container cleaning steps:

1) The cleaning steps of container caps, liners, joints and screw caps (made of Teflon PFA, TFM) are as follows:

a. Rinse all surfaces thoroughly with hot water;

b. Dry all surfaces before use;

c. Repeat step a, rinse again with acetone, then blow dry or wipe off all dirt on the surface with a lint-free towel;

Cleaning of the sleeve. The sleeve is made of high-grade composite materials and cannot touch samples and reagents. The cleaning steps are as follows:

d. Simply rinse with hot water;

e. Blow dry or dry with a lint-free towel;

f. The sleeve should not be soaked in water or detergent for too long;

g. When the above manual cleaning cannot be completed, please add acid for microwave cleaning according to the machine program.

Product instructions:

Weigh 0.2 g to 0.5 g of solid sample (accurate to 0.001 g), 0.2 g to 0.8 g of fresh sample or 1 mL to 3 mL of liquid sample into the digestion vessel, add 5 mL to 8 mL of nitric acid, cover the lid and leave it overnight, tighten the vessel lid tightly. Digest according to the standard operating procedures of the microwave digestion instrument, take it out after cooling, and slowly open the jar lid to exhaust. Rinse the inner cover with a small amount of water, and place the digestion vessel on a temperature-controlled electric heating plate or an ultrasonic water bath, heating at 80 ℃ or ultrasonic degassing for 2 minutes to 5 minutes to drive off the brown gas, and take out the digestion inner liner.

Transfer the digestive juice to a 25 mL plastic volumetric flask, wash the inner liner three times with a small amount of water, combine the washing solution into the volumetric flask and adjust the volume to the mark, mix well and set aside, meanwhile, conduct a blank test.

Reference Conditions of Microwave Digester:

Reference conditions for digestion of grain, vegetable and fish samples

| Step | Power(1600W) Variety% | Temperature℃ | Heating time(min) | Holding time(min) |

| 1 | 50 | 80 | 30 | 5 |

| 2 | 80 | 120 | 30 | 7 |

| 3 | 100 | 160 | 30 | 5 |