Views: 0 Author: Site Editor Publish Time: 2025-12-15 Origin: Site

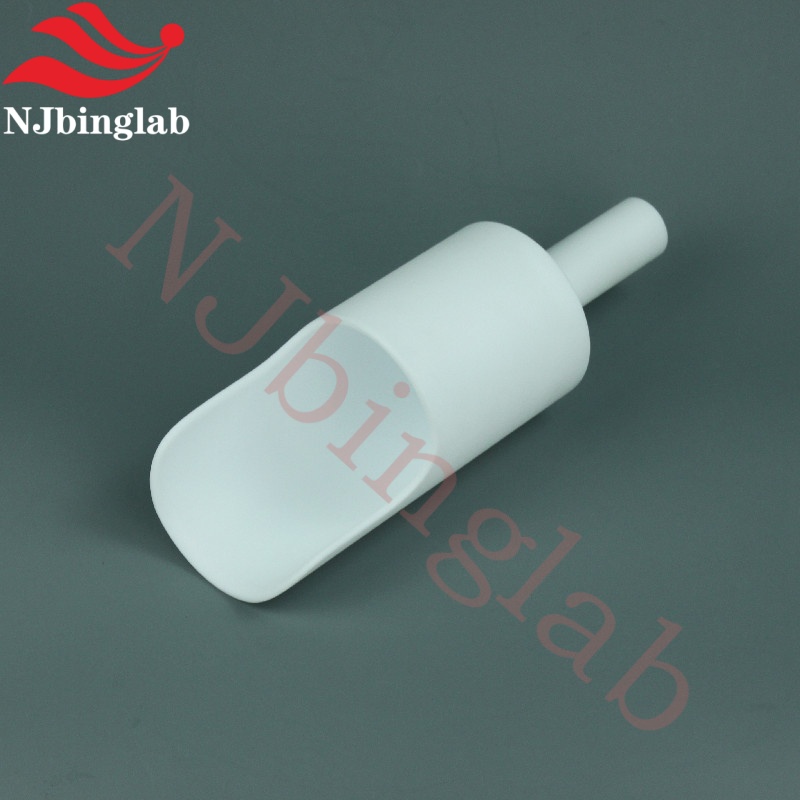

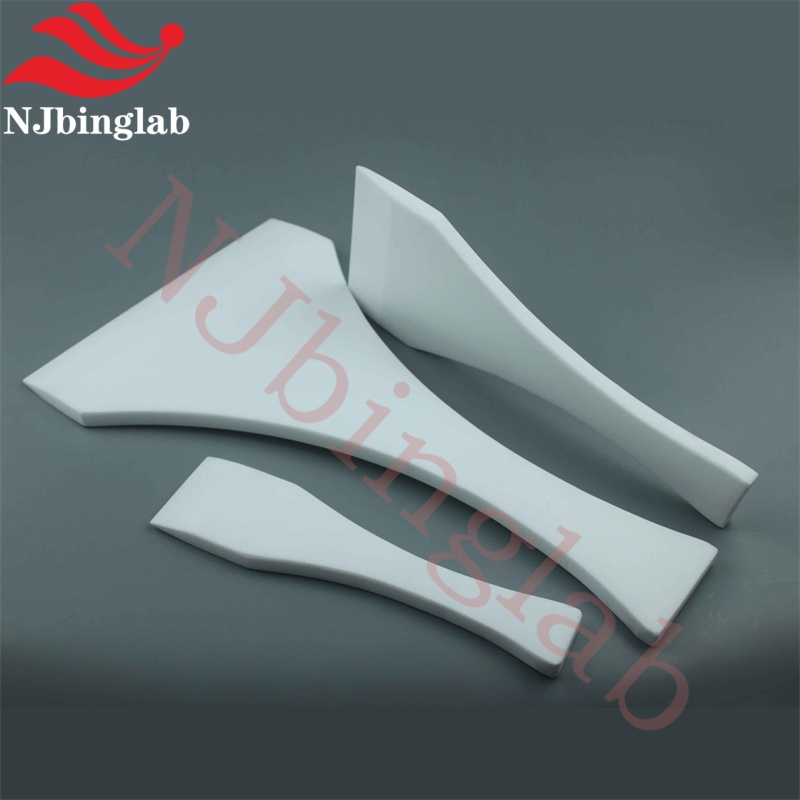

PTFE Scoop/Shovel/Scrapers/Spoons are ideal for material handling, sampling, stirring, and scraping operations in industries such as chemical, pharmaceutical, semiconductor, food, laboratory, and new energy, where high demands are placed on cleanliness and corrosion resistance, due to their corrosion resistance, high temperature resistance, non-stick properties, and high purity. Customized designs further enhance their suitability and professionalism in specific applications.

Characteristics of PTFE (Polytetrafluoroethylene) material:

1.Extremely high chemical stability

Resistant to strong acids, strong bases, organic solvents, and most chemical reagents; reacts with virtually no other substances.

Suitable for highly corrosive environments.

2.Excellent temperature resistance

Wide operating temperature range, generally between -200°C and +260°C.

3.Extremely low surface energy, excellent non-stick properties

Materials do not easily adhere to the surface, making it easy to clean.

4.High purity, no contamination

Free of plasticizers, heavy metals, and other impurities, suitable for applications requiring extremely high levels of cleanliness.

5.Good electrical insulation properties

Suitable for use in the electronics and electrical industries.

6.Moderate mechanical properties, but average wear resistance

Suitable for light to moderate scraping, stirring, and material transfer applications.

Product Features

Shovel: Used for scooping and transferring powdered, granular, or paste-like materials.

Scraper: Used for scraping materials adhering to the inner walls of containers, and also for spreading and mixing.

Spoon: Used for precise measuring, dispensing, and stirring liquids or powders.

Applications and Industries

1. Chemical and Pharmaceutical Industries

Applications: Stirring and transferring corrosive chemicals, high-purity raw materials, and pharmaceutical intermediates.

Advantages: Corrosion-resistant, non-contaminating to materials, easy to clean, and suitable for high-temperature sterilization.

2. Semiconductor and Electronics Industries

Applications: Used in wafer cleaning, photoresist coating, and chemical transfer processes.

Advantages: High purity, dust-free, anti-static, and chemically resistant.

3. Food and Biotechnology Industries

Applications: Used in food processing, fermentation, bioreactor sampling, and culture medium preparation.

Advantages: Complies with food-grade standards, easy to disinfect, non-stick, and odorless.

4. Laboratories and Research Institutions

Applications: Used in chemical experiments, material preparation, sample collection, and container cleaning.

Advantages: Resistant to various reagents, easy to clean, reusable, and does not interfere with experimental results.

5. Coatings and Adhesives Industries

Applications: Used for scraping paint cans, mixing pigments, and sample testing.

Advantages: Non-stick, easy to clean, and solvent-resistant.

6. New Energy Battery Industry

Applications: Used for electrode slurry stirring, coating, and sampling.

Advantages: Resistant to electrolyte corrosion and does not introduce impurities.