Approximately 60% of the analytical errors throughout the detection and analysis process originate from the sample pretreatment rather than the instrument itself. Therefore, sample pretreatment techniques for inorganic metal elements are particularly important. How should pretreatment be done? Let’s take a look.

electric hot plate method, dry ashing method and so on. Among them, microwave digestion method and graphite digestion method have the characteristics of fast heating, high temperature rise, strong digestion ability, low blank value and high efficiency, which are widely used in the pretreatment of inorganic metal elements in animal tissues, plants, blood, food, water, soil and other samples. This article will focus on these two pretreatment solutions in combination with the existing pretreatment equipment in the analytical testing center.

Microwave digestion method

*Principle of microwave digestion

Microwave digestion technology is the use of microwave penetration and activation reaction ability to heat the reagents and samples in a closed container, which can increase the pressure in the sample-making vessel and increase the reaction temperature, thus greatly improving the reaction rate and shortening the sample preparation time, and the reaction conditions can be controlled to make the sample preparation more accurate, reduce the pollution of the environment and improve the working environment of laboratory personnel. The traditional method uses a porous digester or cooking oven preparation method, the sample digestion time takes more than several hours. Even if the more advanced traditional digester, equipped with exhaust gas absorption device, it is difficult to avoid the exhaust gas leakage in the digestion and produce a very choking smell, the use of microwave digestion system sample preparation, digestion time of only tens of minutes, digestion because the digestion tube is completely sealed, no exhaust gas leakage, and does not require toxic catalysts and heating agents.

*Microwave digestion device and parameters

Microwave Digester

Vapor Block

Digestion tube

Power: 220V±10%, 50/60Hz;

Microwave source: 2450MHz, dislocation arrangement of double magnetrons, 0-1600W non-pulsed continuous microwave output, high-frequency closed-loop feedback control;

Installed power: 2000W;

Maximum output power: 1600W;

Microwave resonator: 56L large volume 304 stainless steel cavity, using seamless welding process, 6-layer Teflon coating spray;

Blast door: multi-layer explosion-proof, microwave shielded door;

Software system: 7 inch color touch screen;

Turntable: rotate 360°, rotating speed 10r/min, 8/16/24/40 position rotor, available to place 8/16/24/40 pcs 56ml vessels;

Temperature measurement and control system: 0~300°C measurement range, measurement accuracy is ± 1 ℃ (infrared), and ± 1 ℃ control stability;

Furnace Cavity Exhaust System: Centrifugal exhaust fan, exhaust air volume 5m3/min;

Overall dimensions: 520*640*590cm(width*depth*height);

Total Weight: 61Kg;

Series: MD.

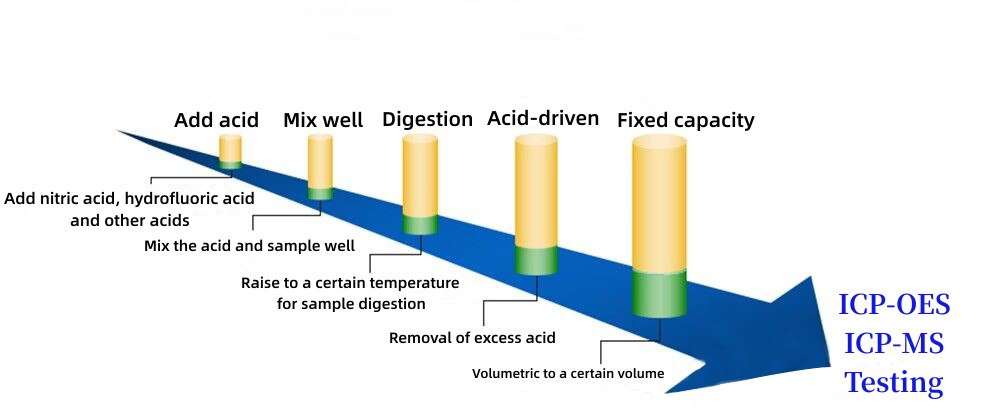

*Sample Handling Process

*Soil Sample Dissolution Case

(1) Freeze-dry the retrieved soil sample, crush and sieve it to remove the larger particles and then weigh 0.1g of the sample in the digestion tank using a one-millionth balance;

(2) Add 6 ml of nitric acid and 2 ml of hydrofluoric acid, screw on the lid and place in the microwave digestion apparatus.

(3) Set the parameters in the program and start the instrument;

(4) At the end of the program run, take out the sample and perform the acid drive;

(5) Drive the acid until it is as dry as possible, fix the volume with 2% nitric acid solution and wait for measurement.

Heating up procedure:

| Step | Temperature(℃) | Heating up time(min) | Keep warm time(min) | Power(W) |

| 1 | 120 | 5 | 3 | 1200 |

| 2 | 160 | 5 | 3 | 1200 |

| 3 | 190 | 5 | 30 | 1200 |

Note: When the number of digestion vessels is 1-20pcs, the power is recommended 1200W; and when it is 21-40pcs, the power is recommended 1600W.

*Animal and plant tissue ablation cases

(1) Freeze-dry the retrieved plant and animal tissue samples, grind them well, and weigh 0.2-0.4 g of the samples in the digestion jar with a one-tenth of a millionth balance;

(2) Add 8 ml of nitric acid, screw on the lid and place it in the microwave digestion apparatus;

(3) Set the parameters in the program and start the instrument.

(4) At the end of the program, take out the sample and carry out acid pick-up;

(5) Drive the acid until it is as dry as possible, fix the volume with 2% nitric acid solution and wait for measurement.

Heating up procedure:

| Step | Temperature(℃) | Heating up time(min) | Keep warm time(min) | Power(W) |

| 1 | 120 | 5 | 3 | 1200 |

| 2 | 160 | 5 | 3 | 1200 |

| 3 | 180 | 5 | 20 | 1200 |

Note: When the number of digestion vessels is 1-20pcs, the power is recommended 1200W; and when it is 21-40pcs, the power is recommended 1600W.

*Attention

(1) Do not turn off the instrument within 5 minutes after stopping the microwave to ensure adequate cooling of the high voltage part of the instrument;

(2) The reagents used in the experimental process must be electronic grade to avoid high background values;

(3) Prohibit running the instrument at no load, and the interval between switching on and off should be more than one minute;

(4) prohibit the use of perchloric acid, alkanes, glycerol and other flammable and explosive samples;

(5) add so that the sample is on the wall of the liner, the amount of solution is not less than 5 ml and not more than 60 ml;

(6) When placing the reaction jars on the turntable, should be as uniform and symmetrical as possible, with a minimum of 8 reaction jars per batch;

(7) For organic matter content, pre-elimination is required to prevent the pressure of the digestion tank from being too high during the digestion process.

Graphite disgestion method

*Principle of Graphite Disintegrator

The graphite digester generates high temperature by heating the graphite block to digest the sample placed in the digestion tube. The new fully automatic graphite digestion instrument is a special sample pre-treatment system for inorganic element analysis, providing a one-stop solution for inorganic sample pre-treatment. It applies the latest computer control technology to sample digestion, which makes the digestion pre-treatment operation free from tedious manual operation and reduces the error and uncertainty caused by human, thus greatly improving the accuracy and efficiency of the digestion process. It also has the functions of adding reagents to the sample, heating the sample, shaking and mixing, driving the acid, and fixing the volume, etc. It basically covers the whole sequence of sample digestion operations and automatically generates records for each step.

Automatic Graphite Disintegrator

*Automatic Graphene Disintegrator Device and Parameters

| Model | SGD60 |

| Heating plate material | High quality ultra-pure graphite, coated with Teflon to prevent corrosion |

| Temperature control range | Room Temperature to 240℃ |

| Temperature control accuracy | ±0.1℃ |

| Inter-hole temperature difference | ±1℃ |

| Number of digestion bits | 60bits |

| Digestion tube volume | 50ml |

| Reagent Channels | 8pcs |

| Accuracy of fixed volume | <1%(50ml) |

| Temperature control system | 10-inch color touch screen |

| Power supply | 220V ±10% 50/60Hz |

| Power Rating | 3000W |

| Weight | 82KG |

Accessories digestion tubes

| Volume | 50ml、60ml |

| Material | High purity experimental grade PTFE/imported translucent PFA |

| Operating temperature | 250℃ |

| Matching cover | Polytetrafluoroethylene threaded caps, reflux caps, etc. |

*Sample Handling Process

*Animal and plant tissue ablation cases

(1) Freeze-dry the retrieved plant and animal tissue samples, grind them well, and weigh 0.5g of the samples in the digestion tank with a one-tenth of a millionth of a centimeter balance;

(2) Place the digestion jar in order in the automatic graphite digestion apparatus;

(3) Set the parameters in the program and start the instrument;

(4) At the end of the program, the solution is filtered and collected in a centrifuge tube for measurement.

Heating up procedure:

| Step | Methods | Conditions |

| 1 | Add liquid: nitric acid | 10ml |

| 2 | Shake: 80% | 1min |

| 3 | Heat: 120℃ | 30min |

| 4 | Heat: 140℃ | 60min |

| 5 | Heat: 160℃ | 30min |

| 6 | Add liquid: nitric acid | 3ml |

| 7 | Shake: 80% | 1min |

| 8 | Heat: 160℃ | 30min |

| 9 | Heat: 160℃ | 60min |

| 10 | Cool down | 20min |

| 11 | Fixing volume: 2% nitric acid solution | 50ml |

*Attention

(1) The instrument should be placed in a fume hood or at a vent to remove the acid mist generated during the digestion process in a timely manner;

(2) Before operating the instrument, make sure that the instrument configuration parameters are appropriate to ensure normal operation of the equipment;

(3) Ensure that the discharge pipe connected to the waste tank is suspended above the liquid level of the waste collection bottle;

(4) The purity of the acid used is electronic grade to avoid high background values.

Summary

Inorganic metal analysis, sample pre-treatment techniques greatly affect the results of the experiment. Therefore, it is especially important to choose the appropriate pretreatment equipment and master the correct sample pretreatment operation techniques. At present, microwave digestion method and fully automatic graphite digestion method are widely used in inorganic pretreatment of environment, animal, plant and food with strong digestion capacity, high efficiency, less pollution and full automation. The experimental process should be based on the type of samples, experimental needs, the selection of appropriate instruments and equipment, the development of personalized experimental program to ensure the accuracy of the detection data.